|

|

|

BIODIESEL FUEL PRODUCER INFORMATION

INDUSTRIAL GRADE BIODIESEL FUEL PRODUCER UNIT

|

|

|

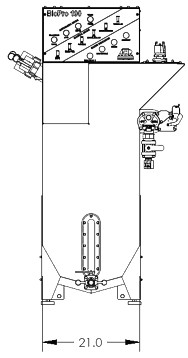

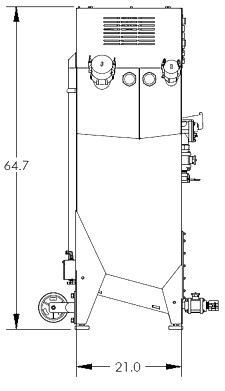

BioPro 190 Automated Biodiesel Processor

Make Clean Burning, 100% BioDiesel Fuel!

Power your Truck, Car, Tractor, Generator, or any other

Diesel Equipment for under 80 cents per Gallon!

The first fully automated, industrial grade biodiesel processor designed for individual, commercial and agricultural use. This state-of-the-art system is easy to use. Extremely versatile, it uses fresh or used vegetable oils. The BioPro 190 is designed for just about anyone who wants to economically produce their own, clean burning 100% biodiesel fuel.

The compact, portable design is self contained with individual sealed compartments for each ingredient required to produce biodiesel. No measuring or mixing chemicals required. Simply add vegetable oil (new or used), methanol, and small amounts of sulfuric acid and lye, and start the automated process. In about 48 hours you will have approximately 50 gallons of clean, smooth-running biodiesel with minimal operator involvement. The patented logic controller has built-in fault protection, providing self-monitoring and step-by-step guidance to the operator. When finished, simply fill your tank with the integrated, 12 G.P.M. fuel pump!

Minimum Requirements

- 50 Gallons of used or new vegetable oil or animal fat

- Methanol; Sodium Hydroxide (Lye); Sulfuric Acid

- Approx. 45 gallons fresh water

- Standard 110vac/15 amp dedicated power source

- Air tight storage containers for methanol, lye and sulfuric acid

- Safety equipment - rubber gloves, eye protection, rubber apron

Specifications

Dimensions: 37"w x 35"d x 67"h

Weight: 275 Lbs (empty)

Capacity: 50 gls. oil yields approx. 50 gls. biodiesel

Construction: TIG welded stainless steel body; Powdercoated steel covers

Fittings: 304 stainless steel or glass filled polypropylene

Electrical: 110vAC / 15 Amp circuit; Max 1100 Watts

Reaction Method: Acid-catalyzed, two-stage transesterification

Wash Method: Triple-stage turbulent water wash

Process Time: Approx. 48 hours

|

|

|

|

|

|

email: portadrillmini@windstream.net

call : 305-345-7068

unit cost $9,999.99 plus shipping cost

|

|

|

|

|

|

|

|

|

|

Advancing Alternative Energy for Today’s and Tomorrow’s Environment

|

|

|

|

|

|

|

|

|

Benefits Of Owning A BioPro 190 Automated Biodiesel Processor 1- Less User Time Making The Biodiesel As they say, time is money and this is where we think the BioPro 190 really shines. To brew a batch of Biodiesel using the BioPro 190 takes about 30-45 minutes of actual user interaction time. The rest is done by the machine. The benefit to you is that instead of having to monitor the machine through its whole process, you just put the oil, chemicals, and methanol in the machine, press a button & walk away. Instead of monitoring the thing & hoping it works right, you're able to concentrate on more important things. 2- Ease Of Use The BioPro 190 is incredibly simple to use. No titrations, no fiddling with ball valves, no transferring hot liquids, none of that. Just pour everything into the machine, push a button and walk away. While other machines on the market require a lot of work and a fair amount of chemistry background, the BioPro 190 just requires the ability to measure & pour...and, oh yeah, push a big button. If you can operate a dishwasher then you can run a BioPro 190. It's really just that easy! 3- Industrial Grade Components The BioPro 190 was designed FROM THE START with longevity in mind. It's built with high-quality, top-notch, name brand components. Not cheap "Made In China" knock-offs, but the real stuff. Things like Stainless Steel, Viton Seals, High-Grade Chemical Pumps, and a Program Logic Controller (Yes, it really DOES have a brain!). It even has one of the highest quality fuel transfer pumps mounted right to it, not some cheap knock-off. Unlike other commercially available processors on the market, the BioPro 190 will last! It's built to give you years of trouble-free performance, year after year after year. And, unlike other's on the market, the BioPro 190 can be run 24/7. It was DESIGNED for that! You also won't see any cracking PVC ball valves, cheap plastic, or other low quality components. It's nothing but the best on this machine! 4- Quick Turn Around Time The BioPro 190 can put out up to 50 gallons of biodiesel every 48 hours. Time after time after time. In fact, if you ran it constantly, you could potentially make 150 gallons of biodiesel a week! While many units on the market boast a quick turnaround time and then in the small print give you lengthy washing and drying times, the BioPro 190 gives an honest 50 gallons in 48 hours. 5- Small Footprint The BioPro 190 takes up a relatively small amount of space when compared to the competition. Instead of a big, bulky processing tank, a large methoxide tank, and a washing tank, the BioPro 190 integrates all of these into a single, compact unit. What you see is what you get. You don't need any extra overprice expansion tanks or flimsy stands for this unit. Just a source of water, a standard 120 volt outlet, and you're set! 6- It'll Save You Money It will save you a lot of money. Based on our BioPro 190 Cost Analysis you can save nearly $3.00 a gallon on fuel costs by brewing your own biodiesel with a BioPro 190. And, within a fairly short period of time, the machine pay's for itself!

|

|

|

|

How The BioPro 190 Automated Biodiesel Processor Works

The BioPro 190 (BP-190) converts organic oils into an alternative to diesel fuel called Biodiesel through a chemical process. The common name for the process is called an acid/base catalyzation. It's just a fancy word meaning that the oil is chemically altered to allow it to run in an unmodified diesel engine.

What's unique about the BioPro 190 is that the majority of this process is done by the machine with very little user interaction. Instead of having to turn valves, meter in chemicals, and carefully monitor the machine, you just pour everything in, press a button and walk away.

Before starting the process, the user simply fills the machine with 50 gallons of filtered, dewatered oil. The oil can be any organic oil (tallow, fats, vegetable oil, etc), but in most cases, waste vegetable oil is the most commonly used feedstock to make biodiesel with due to it's wide availability.

After filling the machine with oil, the user fills the machine with a predetermined amount of catalyst and methanol. The catalyst is easily weighed and placed in the machine. The methanol is then added to the machine. The final step is to measure out the proper amount of sulfuric acid. The user then presses "The Big Green Button", waits for the mixing to start and then pours the sulfuric acid into the machine. And then, get this, THE USER WALKS AWAY allowing the machine to do its work. There is absolutely no need to monitor the machine at all. It does the majority of its work all by itself!

After the button is pushed and the machine is started, here's a breakdown of how the machine converts the oil feedstock into clean, crystal clear, ready to use Biodiesel.

REACTION 1 - ESTERIFICATION a.k.a. the "Acid" stage

During this stage, the machine mixes sulfuric acid and a portion of the methanol into the oil. The sulfuric acid goes on the hunt for free fatty acids and modifies them so that the methanol can attach to them and create biodiesel.

Over the course of a few hours a lot of heating and mixing will occur to make sure that the acid and the methanol have had a chance to do their job. This is because a thorough Acid stage helps to make the Base stage successful

REACTION 2 - TRANSESTERIFICATION a.k.a. the "Base" stage

After the acid stage has occurred it's time for the real action to get started. In this stage the machine mixes in the Base catalyst and the rest of the methanol. During this stage, the catalyst, which is usually Lye (Sodium Hydroxide - NaOH) or Caustic Potash (Potassium Hydroxide - KOH), attacks the oil and begins breaking the molecules apart into glycerol and fatty acid chains (the catalyst used is extremely powerful!). Just after the molecules are broken apart the methanol begins to attach to the fatty acid chains. This causes the glycerol molecules to begin to drop out of the mixture into a mixture called glycerin.

This stage takes several hours to occur as well. While this stage is happening the machine is mixing the oil, chemicals, and methanol together with an extremely powerful, tri-blade impeller. This helps to really mix things together and helps ensure that all of the oil has a chance to be chemically altered.

SETTLING PERIOD - a.k.a. Glycerin Drop Out

After both reactions have occured, the oil is allowed to settle for a period of time. This allows the glycerin to fall to the bottom of the tank and separate away from the freshly made biodiesel. The settling can take several hours and helps to ensure that everything settles out properly.

MID POINT - DRAIN GLYCERIN

At this point, the user comes back to the machine and drains out the settled glycerin and begins the washing cycle. This is the only user interaction during the processing that's required.

WASHING BEGINS

The BioPro 190 now begins the washing part of the process. During this process, the machine will turn on the heat and lightly spray a mist of clean, fresh water into the biodiesel to begin the process of cleaning the biodiesel. It may sound strange to add water to biodiesel, but it works. Because water is heavier than biodiesel, it quickly falls to the bottom.

As the water falls, excess methanol and soap molecules attach to the water and fall with it, thereby cleansing the biodiesel. After the first mist wash, the water is then drained out and another mist wash is performed, only this time the big tri-blade mixing impeller comes on mixing the water and the biodiesel together to create a wonderful washing action. They call it an "agitated wash cycle" and agitate it does! It mixes the water thoroughly with the biodiesel so that it pulls the most impurities it can out of the biodiesel.

The machine then lets everything settle for a few hours, drains off the water and starts another agitated mist wash. In an effort to cleanse the biodiesel the best it can, the machine performs this last wash cycle with the massive tri-blade impeller going in full force. Once it's done the water settles to the bottom and is automatically pumped out by the machine.

DRYING BEGINS

Now the final settling stage begins. After the wash water has been drained off, the heat remains on and the tri-blade impeller kicks in again. The combination of the heat and the mixing help to evaporte any excess water from the freshly washed biodiesel. After the heat & mixing is done the BioPro allows the biodiesel to settle out one last time. During this time the now heated biodiesel evaporates off any excess water. When the process is complete, you're left with a nice, clear looking tank of biodiesel that is ready to use!

And that's it! That's all there is to it. Instead of having to transfer everything around from container to container the machine does it all for you. When it's completed you can even hook up the hose to the included fuel pump and pump the finished biodiesel right into your vehicle! How's that for automation!

We hope this page has helped you see just how amazing this machine really is. We firmly believe in this product and think it's incredible! After homebrewing biodiesel for quite some time now using equipment that required a lot more work, we've fallen in love with this machine. We're sure you will too!

If you'd like to learn more about how the machine works or just have a general question for us about it, feel free to contact us.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|